Axess Group is your strategic partner in achieving long-term benefits. Over the past 20 years, we have developed competencies within the

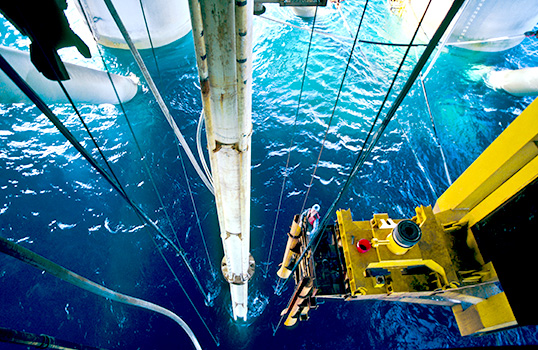

drilling sector, providing inspection services for different types of rig equipment, according to the relevant regulatory standards. Our vast project portfolio serves as a testimony to our expertise, with successful inspections and assessments worldwide.

Our comprehensive range of inspections for drilling rigs is focused on enhancing technical integrity for reliable operations, improving health and safety for crew, as well as achieving compliance with national and international regulations. Our rig inspection strategies are specifically designed for our partners in the offshore drilling industry. Some of our services include dimensional control, NDT inspections, visual inspections and function testing.

With our Risk-Based Inspection (RBI) framework by means of

Non-Destructive Testing (NDT), we are able to prioritise inspection and zone in on the equipment’s true state, which is a vital element in ensuring optimal operations at minimum cost.

Following our thorough inspection, we assess the results, deliver effective and cost-efficient solutions for assets that are most at risk, and provide our clients with targeted analyses. We can also provide reports of the thorough examination carried out by a competent person as required by Lifting Operations and Lifting Equipment Regulations (LOLER).

This results in a number of benefits, such as:

- compliance with our partners’ requirements;

- the ability to combine delivery to execute NDT needed and Enterprise of Competence;

- compliance with rules and regulations (NORSOK, LOLER, CAPP, API, ILO 152);

- safe drilling operations;

- and verification on the status of inventory.

Our integrated approach allows us to provide our clients with tailored solutions. Aside from drilling equipment inspection, we can design a multi-level programme that employs strategies and methodologies to assess the different aspects of our clients’ businesses.